The two-in-one feeding station for small bags of tons can realize both the feeding and packaging of small bags, realize the feeding of materials with multiple packaging specifications in the same equipment, and has small floor area and light overall structure. Compared with the traditional feeding equipment, this equipment has the following advantages:

1) It can meet the requirements of ton bag feeding and various specifications of small bag feeding;

2) The equipment is in the form of bag pressing. When feeding a ton bag, press the outer bag of the ton bag tightly with the equipment, and then unpack the bag inside the feeding port. After unpacking, close the unpacking port to prevent dust leakage;

3) Equipped with a dust collection system, which can return the collected dust to the feeding station to reduce the dust leakage during the feeding process and avoid the waste of materials;

4) The equipment has the function of auxiliary unloading (tapping). When there is too little material in the ton bag, the auxiliary unloading is turned on, which can reduce the feeding time;

5) The inner part is equipped with a grate to prevent foreign matters and bulk materials from entering during feeding;

6) The lower part is equipped with auxiliary unloading device to ensure that all materials in the feeding station enter the downstream equipment;

7) The equipment can also be equipped with a bar code misplacement device to prevent workers from feeding errors, so as to facilitate the overall matching and overall control with other automatic equipment;

8) Castors can be installed at the anchor to facilitate the flexible movement of the equipment.

I. Working principle

The material dust generated during feeding is sucked into the filter system by the negative pressure formed by the centrifugal fan or the air extraction pipe to separate the material from the air, prevent the dust from escaping, pollute the surrounding environment and protect the health of the operator.

II. Main structure

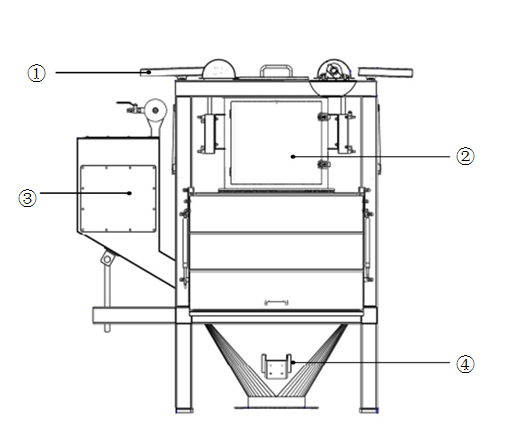

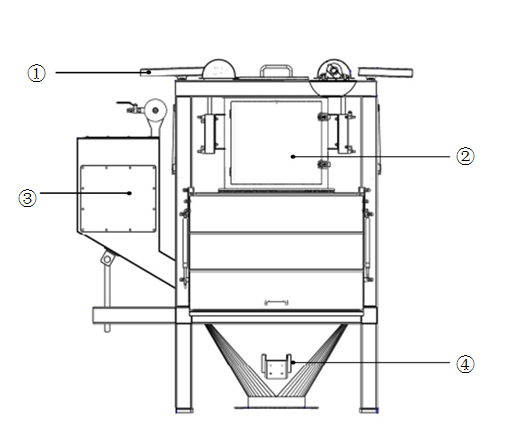

① Flapping device ② Receiving silo assembly ③ Dust collection assembly ④ Feeding station silo body